Phone:

(701)814-6992

Physical address:

6296 Donnelly Plaza

Ratkeville, Bahamas.

Concrete plywood is typically a general term for plywood used in forming. Formply is usually a purpose-made product with a factory-applied film face designed specifically for concrete contact and re-use.

Concrete plywood is usually structural plywood—often F14 plywood—selected for temporary formwork, sometimes sealed or oiled on-site to reduce sticking and water uptake. It can work well, but its performance depends heavily on grade, species, glue bond, and proper edge sealing.

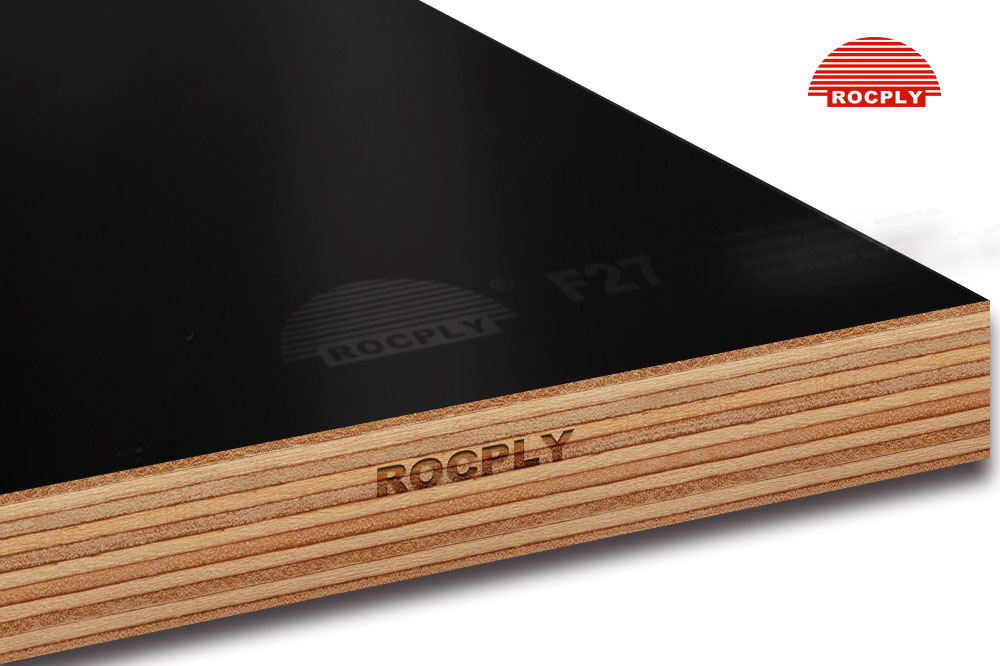

Formply, by contrast, is a plywood panel with a phenolic film (or similar) bonded to the faces. That film creates a smoother, more water-resistant surface and is specifically designed to handle repeated concrete pours with less surface breakdown.

Formply generally performs better in wet conditions because the film face slows water penetration and reduces surface checking. It is also less likely to delaminate when handled correctly, especially when edges are sealed and damage is repaired.

Concrete plywood can absorb water faster through faces and edges. If they do not seal edges well, store it off the ground, and avoid prolonged saturation, it tends to swell, warp, and lose face integrity sooner.

Formply usually gives a cleaner, more consistent finish because the film face is smooth and non-porous. They will often see fewer grain marks, fewer surface defects, and less tearing when stripping forms, especially if release agent is applied properly.

Concrete plywood can leave a more timber-textured finish and may show patchiness over multiple pours. If its face veneer is rough or damaged, concrete pickup and surface blemishes become more likely.

In many cases, strength is less about “concrete plywood vs formply” and more about the structural rating, thickness, and span support details. A high-grade structural plywood panel can be very strong in bending if they choose the right thickness and brace it correctly.

Formply’s key advantage is surface durability rather than raw structural capacity. That said, many formply products are manufactured to formwork standards, so they often provide predictable stiffness and stability when used as intended.

Formply typically wins for reusability. If they avoid gouges, keep it clean, patch film damage, and reseal edges, it can handle many cycles before the face degrades.

Concrete plywood can be economical for one-off or low-cycle jobs, but it usually breaks down faster. The face veneer may lift, edges may fray, and concrete bond can increase, reducing the number of usable reuses.

Concrete plywood can be cheaper upfront, which suits projects where they expect limited reuse or where sheets may be cut into small sections and discarded. It can make sense when the formwork is highly bespoke and waste is inevitable.

Formply usually costs more per sheet, but its longer service life often lowers cost per pour. If they plan multiple pours and can store and handle sheets carefully, formply tends to pay back quickly.

Concrete plywood is often easier to cut and patch without worrying about maintaining a film surface. They can seal cuts and faces with common site practices, but consistency depends on workmanship.

Formply cuts cleanly, but they must reseal every cut edge and repair face damage to protect the panel. If they ignore small punctures, water can creep in and shorten panel life.

They should choose formply when they need a smooth finish, high reusability, and better moisture resistance, especially on repeat pours or commercial work where consistency matters. It is usually the safer choice when downtime, patching, and replacement would be costly.

They should choose concrete plywood when the job is low-cycle, the finish requirements are relaxed, the forms are complex and disposable, or the budget is tight and replacement is expected. The best results come when they select a suitable structural grade and seal edges properly.

If they want the best chance of strong reuse and a clean finish, they should lean toward formply. If they only need a few pours and can accept faster wear, concrete plywood can be the practical pick.

Performance is less about the label and more about how well the sheet is rated, supported, protected at the edges, and treated between pours.

Concrete plywood is structural plywood used for temporary formwork, often sealed or oiled on-site to reduce sticking and water uptake. Formply is a purpose-made plywood panel with a factory-applied phenolic film face designed specifically for concrete contact and re-use, providing a smoother, more water-resistant surface.

Formply generally performs better in wet conditions due to its film face that slows water penetration and reduces surface checking. Concrete plywood can absorb water faster through faces and edges, leading to swelling, warping, and loss of face integrity if not properly sealed and stored.

Formply usually gives a cleaner, more consistent finish because its smooth, non-porous film face results in fewer grain marks and surface defects. Concrete plywood tends to leave a more timber-textured finish and may show patchiness over multiple pours.

Strength depends more on structural rating, thickness, and support rather than the type of sheet. High-grade structural plywood can be very strong if properly supported. Formply’s main advantage lies in surface durability rather than raw structural capacity but often meets formwork standards for predictable stiffness and stability.

Formply typically lasts longer due to its durable film face that withstands repeated pours when properly maintained by patching damage and resealing edges. Concrete plywood is more economical for low-cycle jobs but degrades faster with face veneer lifting and edge fraying reducing reuse potential.

Choose formply for smooth finishes, high reusability, better moisture resistance, especially on repeat pours or commercial work where consistency matters. Opt for concrete plywood when the job is low-cycle with relaxed finish requirements, complex disposable forms, tight budgets, or expected replacement. Proper grade selection and edge sealing are crucial for best results.

Related : F14 Grade Plywood: Where Is It Required in Construction?